Services

Complete Mechanical Engineering Capabilities

- Mechanism Design

- 3d Cad Cleanup & 2d drawings

- Structural, Thermal and Fluid Analysis

- Detailed technical specifications and product requirements

- Design optimization

- Rapid prototyping

- Regulatory compliance

- Manufacturability and sustainability assessments

- Pre-production, fabrication, and manufacturing support

- Product assembly instructions and documentation.

- Schematic Electrical Drafting.

- CAD Electrical Drafting Layouts.

- Electrical Design Services.

- Wire harness Design

- Electrical Engineering Power System Designs.

- Interior and Exterior Lighting Design Services.

Finite Element Analysis:

- Linear/Nonlinear Analysis

- Fracture/Fatigue Analysis

- Static Stress Analysis

- Buckling Analysis

- Dynamic Impact, Drop Test

- Thermal Analysis

- Modal Analysis

- Multiphysics Analysis

- Random Vibration / Seismic

- Design/Shape Optimization

- Harmonic Analysis

- Electromagnetics Analysis.

- Forming Analysis

CFD Simulation

- Steady Flow Analysis

- Mass Transfer CFD simulation

- Free Surface Flow and Cavitation

- Chemical Reaction, Combustion

- Multiphase Flow / Particle Track

- Heat Transfers

- Multiple Streams

- Laminar/Turbulent Analysis

- Transient Flow analysis

- Dynamic Cell Addition/Deletion

- Acoustics / Liquid / Gas

- Motion and Multiphysics

- Rotating Machinery

- Newtonian/Non-Newtonian Flow Analysis

Mould Flow Analysis

- Injection Moulding

- Multi-Component Moulding

- Gas-Assisted Injection Mould

- Injection Gate Optimization

- Flow / Pack Analysis

- Hot Runner Optimization

- Warpage Analysis

- Cooling Analysis / Design

- Multi-Shot, Insert, Over Moulding

1) Injection Moulding Simulation:

- Dimensional control: Tolerances, deformation, shrinkage

- Surface quality: Blemish delete

- Stress evaluation

3) Mould:

Develop and support mould design. Manage issues related to:

- Feeding (hot runner, cold runner, position and balancing)

- Conditioning (sizing, balancing, special insert)

- Plastic material (selection, test new material)

- Mechanic (shrinkage, cavity, inserts, vents)

2)Product development:

Develop products respecting dimensional, quality and standards requirements. Provide advice and support to optimize product and solve issues found during the production.

4)Moulding:

Support the choice of components and process parameters in order to reduce issues during the production and to solve defects in the products:

- Support choice of material and press

- Optimization

- Process parameters

- Close pressure

- Shrinkage

- Junction lineand air trap

- Surface blemish and suction mark

- Cycle time

- Costs

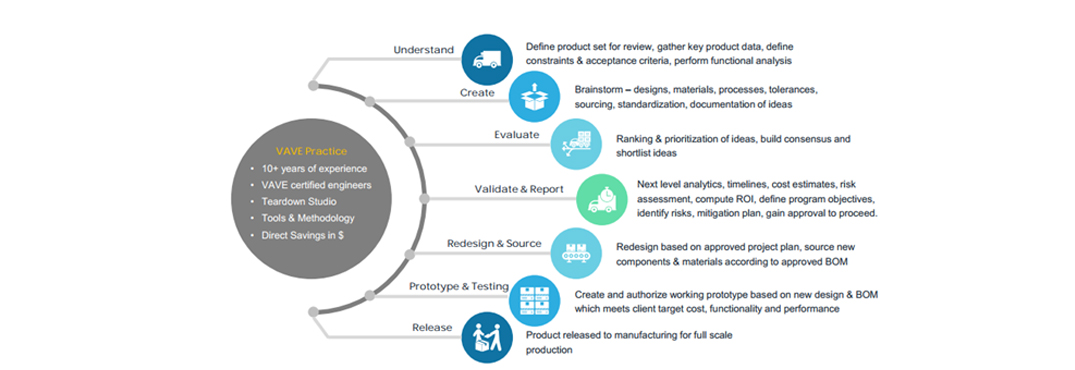

1) CONCEPT TO PRODUCT

Providing turnkey solutions that transform concepts into marketable products.

2) PRODUCT TO PRODUCT

Transform an existing product to meet emerging market needs using obsolescence management and localization through our value engineering services.

3) SUSTAINING SERVICES

Sustain your products across the full life cycle, designing serviceability and sustainability into your product from the start, proactively extending product life, and building long-term value for your brand.

4) DESIGN TO PRODUCT

Transform a validated concept to design, prototype, qualification, and series production.

5) BUILD TO PRINT

Transition a validated product into execution through our manufacturing services.

Over the years, the variety of models in many companies has increased significantly. This raises the pressure to keep track of your company’s efficiency and inventories, despite the product variety. With our “Global/Technical Product Standardization” consulting service, we help you define clear regulations for product design engineering. Using consistent standards and engineering principles, the part diversity and engineering variations are minimized, and common product processing features are created. This leads to simplified production. And yet, the main priority is that clients and designers must not be restricted. Increase the efficiency of your entire organization by implementing an intelligent product design which ideally combines product demands and requirements.

Benefits

- Reduction in manufacturing costs.

- Increase in the machine utilization rate.

- Shorter retooling times and lead times.

- Reduction of inventories.

- Greater product variety due to more combination possibilities.

- Increased output in production, thanks to consistent manufacturing processes and simplified production.